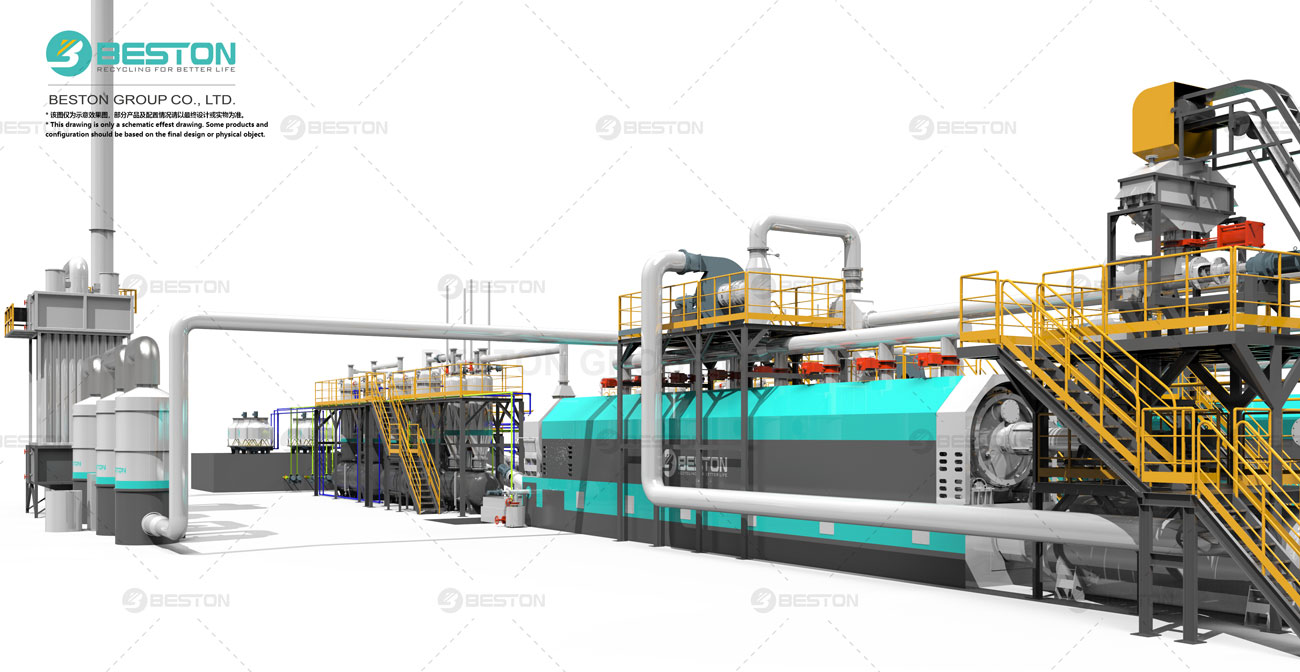

In the realm of pyrolysis equipment, continuous pyrolysis plants stand out as a pinnacle of innovation and efficiency. If you're contemplating an investment in pyrolysis machinery, directing your focus towards a continuous pyrolysis plant can unlock a myriad of advantages that other alternatives might not offer. Here's why delving into the world of Beston continuous pyrolysis equipment might be your most prudent choice.

Amplified Processing Capacity

A defining advantage of continuous pyrolysis plants lies in their unparalleled processing capacity. Especially when contrasted with their batch counterparts, continuous plants shine as production powerhouses. If your business is geared towards ambitious production goals, a continuous plant can be your reliable ally in consistently meeting and exceeding those objectives.

Unlike batch plants, continuous pyrolysis plants operate with remarkable efficiency and can be a prime solution for converting waste materials into valuable resources such as oil. Their high processing capacity not only translates to efficiency but also directly correlates to the potential for higher profits. When assessing machinery options, the processing capacity should be a leading consideration, and continuous plants undeniably excel in this aspect.

Seamless Automation

In the world of continuous pyrolysis plants, automation is a guiding principle. These plants operate with minimal intervention once set in motion. While tire after tire gets transformed into valuable resources, minimal human involvement is required. The inherent automation boosts overall plant efficiency and optimizes resource utilization.

When you're contemplating machinery options for your pyrolysis venture, the allure of automation cannot be overstated. The less time and labor you need to invest in the plant's operation, the more you can maximize productivity and utilize your time for other essential aspects of your business.

Elevated Oil Yield

One of the most striking advantages of continuous pyrolysis plants is their capacity to deliver a notably higher oil yield. The technology harnessed by these plants ensures that more oil can be extracted from the same quantity of input materials compared to other methods. Considering the immense value of oil as a resource, this higher yield directly translates into enhanced profitability.

Before investing in any pyrolysis machinery, scrutinize the potential oil yield it promises. A continuous plant, with its remarkable ability to yield more oil, could significantly impact your bottom line and accelerate the return on your investment.

Diverse Options for Individual Needs

Choosing a continuous pyrolysis plant doesn't mean limiting your choices. Quite the opposite. These plants come in various types, each with distinct features tailored to different needs. From diverse functionalities to varying price points, continuous plants offer a spectrum of options that can cater to a wide range of priorities and business models.

Your choice of pyrolysis machinery should align with your unique business needs and goals. With the array of options that continuous pyrolysis plants provide, you'll be equipped to secure a supplier who resonates with your vision and acquire machinery that perfectly aligns with your requirements. Take a view at this type: https://bestonmachinery.com/plastic-pyrolysis-plant-cost/.

Embracing the potential of continuous pyrolysis plants can usher your business into a realm of efficiency, elevated productivity, and enhanced profitability. By thoroughly exploring these benefits, you can ensure that the investment you make today paves the way for a lucrative and sustainable future.