Introduction

In recent years, continuous pyrolysis technology has emerged as a transformative force in the realm of solid waste recycling. This advanced method, distinguished by its ability to process waste materials in a continuous flow, offers a sophisticated solution to the pressing issue of waste management. The application of continuous pyrolysis addresses both environmental concerns and resource recovery by converting various waste streams into valuable byproducts. This article delves into how continuous pyrolysis technology is revolutionizing solid waste recycling and its implications for future waste management strategies.

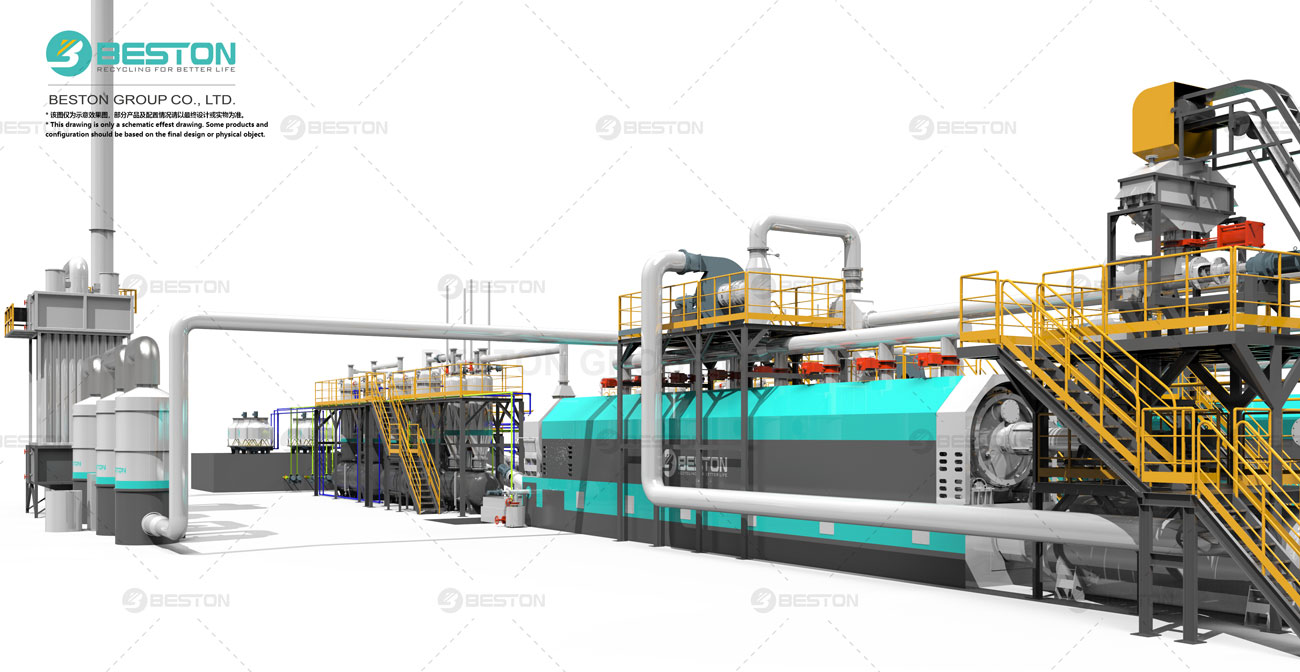

Mechanism of Continuous Pyrolysis

Continuous pyrolysis operates on the principle of thermal decomposition of organic materials in the absence of oxygen. Unlike batch pyrolysis, which processes waste in discrete batches, continuous pyrolysis machine facilitates a constant feed of waste materials into the reactor. This process ensures a steady output of end products, including gases, liquids, and solid residues.

The process begins with the feedstock, which is typically pretreated to reduce its size and enhance its reactivity. Once introduced into the reactor, the waste material undergoes pyrolytic decomposition due to elevated temperatures, usually ranging from 300°C to 700°C. The absence of oxygen prevents combustion, allowing for the production of valuable byproducts without the release of harmful pollutants. This continuous operation not only improves efficiency but also maximizes the yield of high-quality outputs.

Advantages of Continuous Pyrolysis

Enhanced Efficiency

The continuous nature of this technology significantly improves operational efficiency compared to traditional batch systems. Continuous pyrolysis allows for uninterrupted processing, leading to higher throughput and reduced operational costs. The ability to continuously feed waste material into the system also minimizes downtime and enhances overall productivity.

Reduced Environmental Impact

One of the most compelling benefits of continuous pyrolysis is its reduced environmental footprint. By converting waste into valuable byproducts, such as bio-oil and syngas, this technology mitigates the need for landfilling and incineration. The absence of oxygen during pyrolysis minimizes the emission of harmful gases, contributing to a cleaner and more sustainable waste management solution.

Resource Recovery

Continuous pyrolysis is instrumental in resource recovery from solid waste. The process yields several useful byproducts, including bio-oil, which can be further refined into fuels or chemical precursors, and syngas, which can be used as a clean energy source. Additionally, the solid residue, often referred to as char, can be utilized as a soil amendment or in other industrial applications. This ability to extract value from waste materials supports the principles of a circular economy, where resources are reused and recycled rather than disposed of.

Versatility

The technology’s versatility is another significant advantage. Continuous pyrolysis systems are capable of processing a wide range of feedstocks, including plastics, tires, agricultural residues, and municipal solid waste. This adaptability makes continuous pyrolysis an attractive option for diverse waste management scenarios, enabling the treatment of various waste streams with differing characteristics.

Challenges and Considerations

Despite its advantages, continuous pyrolysis technology is not without challenges. The initial capital investment for setting up a continuous pyrolysis system can be substantial, which may deter some potential adopters. Additionally, the need for precise control of operating conditions, such as temperature and feed rate, requires sophisticated monitoring and control systems to ensure optimal performance.

Another consideration is the management of byproducts. While continuous pyrolysis generates valuable outputs, the disposal and handling of residual char and other byproducts must be managed effectively to avoid environmental and economic issues. Ensuring that these byproducts are utilized in a sustainable manner is crucial for maximizing the overall benefits of the technology.

Future Outlook

The future of continuous pyrolysis technology for waste appears promising, with ongoing research and development aimed at improving system efficiency and expanding its applications. Innovations in reactor design, feedstock pretreatment, and byproduct management are expected to enhance the technology’s performance and cost-effectiveness. As the global emphasis on sustainability and waste reduction intensifies, continuous pyrolysis stands to play a pivotal role in advancing waste management practices.

Conclusion

Continuous pyrolysis technology represents a significant advancement in the field of solid waste recycling. Its ability to process waste materials continuously, coupled with its efficiency and environmental benefits, positions it as a key player in modern waste management strategies. By transforming waste into valuable byproducts and reducing reliance on traditional disposal methods, continuous pyrolysis contributes to a more sustainable and resource-efficient future. As technological innovations continue to evolve, the potential for continuous pyrolysis to further revolutionize waste recycling remains substantial, promising continued progress in addressing global waste challenges.