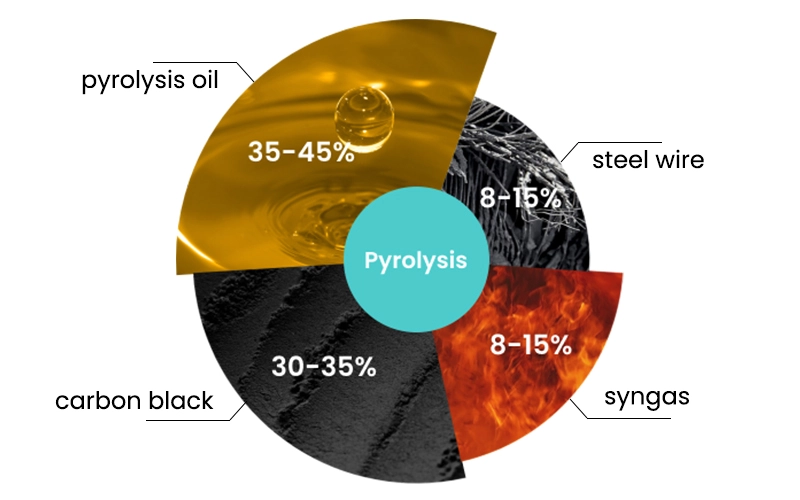

Tyre pyrolysis is a transformative process that decomposes end-of-life tyres into valuable byproducts through controlled thermal degradation. This method not only addresses the growing issue of tyre waste but also produces several economically and environmentally beneficial products. The main end products of tyre pyrolysis are pyrolysis oil, carbon black, syngas, and steel wire, each of which has distinct applications across various industries.

Overview of Tyre Pyrolysis Process

Tyre pyrolysis involves heating tyres by waste tyre pyrolysis plant in the absence of oxygen, breaking down their complex organic compounds into simpler forms. The process occurs at high temperatures, typically between 400°C and 800°C, and results in the production of pyrolysis oil, carbon black, syngas, and steel wire. These products are valuable resources that can be repurposed for different industrial applications.

Applications of Pyrolysis Oil

1. Energy Production

Pyrolysis oil, also known as tire-derived oil, is a liquid byproduct of tyre pyrolysis with significant potential as a fuel source. It can be used directly as a substitute for conventional fossil fuels in industrial burners and furnaces. The high energy content of pyrolysis oil makes it suitable for generating heat and power in various industrial processes, including cement kilns and power plants. By utilizing pyrolysis oil, industries can reduce their reliance on traditional fossil fuels and lower their greenhouse gas emissions.

2. Chemical Feedstock

Pyrolysis oil contains a complex mixture of hydrocarbons, which can be further processed to produce various chemicals and additives. Through refining and upgrading, pyrolysis oil can be converted into valuable chemical feedstocks for the production of solvents, lubricants, and other chemical products. This conversion process helps to maximize the economic value of the oil and supports the circular economy by recycling tyre waste into useful chemical products.

3. Road Construction

In some applications, pyrolysis oil is used in road construction as an additive in asphalt mixtures. Its properties can enhance the performance and durability of asphalt, improving the longevity of road surfaces. This application not only utilizes a byproduct of tyre recycling but also contributes to more sustainable infrastructure development.

Applications of Carbon Black

1. Rubber Industry

Carbon black is a fine, black powder produced from the thermal decomposition of tyres. It is a crucial ingredient in the rubber industry, where it is used as a reinforcing filler in tyres and other rubber products. Carbon black enhances the mechanical properties of rubber, including its strength, durability, and resistance to wear and tear. The rubber industry relies heavily on carbon black for manufacturing high-performance tyres and other rubber components.

2. Pigment and Ink Production

In addition to its use in rubber, carbon black is also employed as a pigment in various applications. It is used in the production of black inks, paints, and coatings due to its deep black color and excellent tinting strength. The versatility of carbon black as a pigment makes it valuable for the manufacturing of a wide range of colored products.

3. Plastic Industry

The plastic industry utilizes carbon black as a colorant and stabilizer in plastic products. It helps improve the UV resistance and overall durability of plastics, making them suitable for outdoor and high-stress applications. The incorporation of carbon black in plastics enhances their performance and extends their service life.

Applications of Syngas

1. Energy Generation

Syngas, or synthesis gas, is a mixture of hydrogen, carbon monoxide, and carbon dioxide produced during tyre pyrolysis. It can be used as a fuel for power generation in gas turbines or internal combustion engines. Syngas is a flexible energy source that can be converted into electricity or heat, providing an efficient and sustainable alternative to conventional energy sources.

2. Chemical Production

Syngas serves as a fundamental building block for the synthesis of various chemicals. It can be used in the production of methanol, ammonia, and other chemical intermediates. By leveraging syngas, industries can produce essential chemicals from tyre waste, reducing the need for raw materials and supporting sustainable chemical manufacturing processes.

3. Hydrogen Production

Syngas can be reformed to produce hydrogen gas, which is a valuable resource for various industrial applications. Hydrogen is used in refining processes, fuel cells, and as a feedstock for producing ammonia and other chemicals. The ability to generate hydrogen from syngas contributes to the development of cleaner energy technologies and supports the transition to a hydrogen economy.

Applications of Steel Wire

1. Recycling and Reuse

Steel wire recovered from tyre to oil plant is a valuable byproduct with several potential applications. It can be recycled and used as raw material in the steel industry for producing new steel products. The recycling of steel wire helps reduce the demand for virgin steel, conserves natural resources, and minimizes environmental impact.

2. Construction and Reinforcement

Steel wire can be repurposed for use in construction and reinforcement applications. It can be used in concrete reinforcement, wire mesh, and other structural applications. The high tensile strength and durability of steel wire make it suitable for enhancing the structural integrity of construction materials.

3. Manufacturing of Wire Products

Recovered steel wire can be processed into various wire products, including fencing, cables, and springs. These products find applications in agriculture, telecommunications, and manufacturing industries. By utilizing steel wire from tyre pyrolysis, industries can create new products while promoting sustainable waste management practices.

Conclusion

The applications of tyre pyrolysis end products—pyrolysis oil, carbon black, syngas, and steel wire—demonstrate the significant potential for recycling and repurposing tyre waste. Each byproduct offers unique advantages across various industries, contributing to more sustainable and efficient waste management solutions. By leveraging these products, industries can reduce their reliance on traditional resources, lower environmental impact, and support a circular economy. The continued development and adoption of tyre pyrolysis technologies will play a crucial role in addressing the challenges of tyre waste and advancing sustainable industrial practices.