Investing in a thermal desorption unit involves a multifaceted evaluation process. This technology, used primarily for the remediation of contaminated soils and industrial waste, requires careful consideration of various factors that can influence both the initial investment and the long-term operational efficiency. Understanding these considerations will enable stakeholders to make informed decisions and optimize their investment in a thermal desorption unit.

Technology and Efficiency

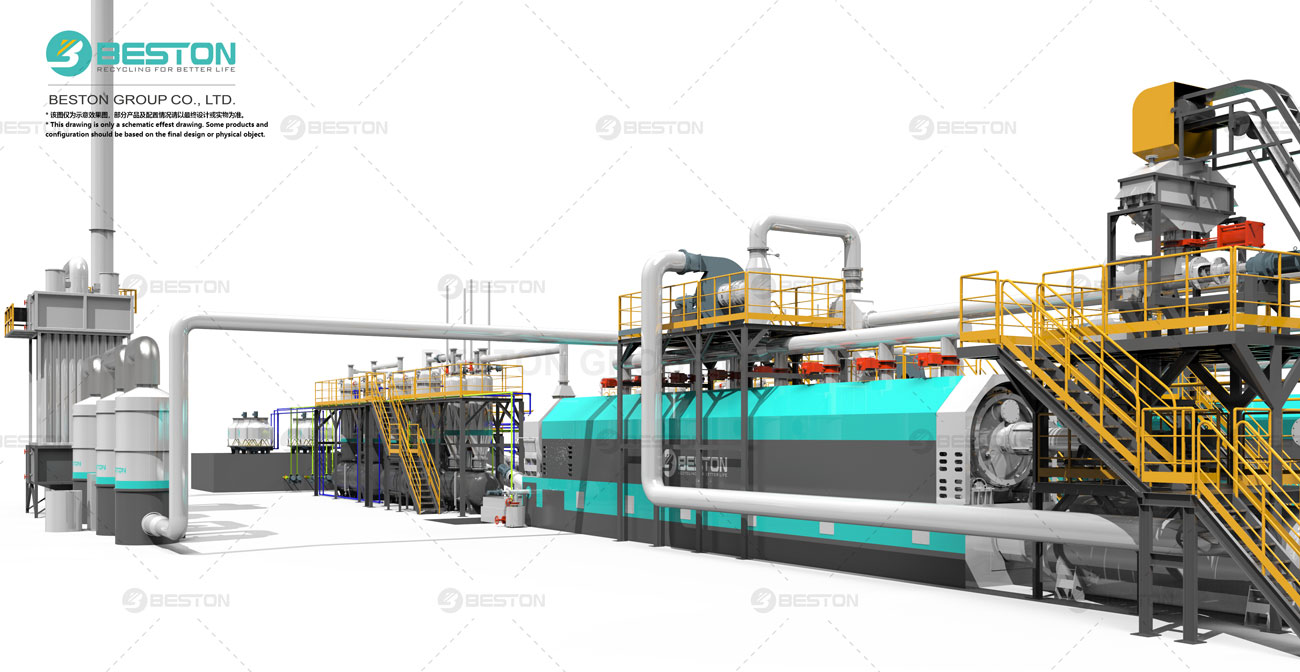

The technological sophistication of a thermal desorption unit significantly impacts its price. Advanced units often feature enhanced thermal management systems, precision control mechanisms, and real-time monitoring capabilities. These features contribute to improved operational efficiency, higher recovery rates of valuable by-products, and reduced energy consumption.

Units equipped with state-of-the-art technology typically command a higher price due to the complexity and integration of advanced systems. However, the long-term benefits of improved efficiency and reduced operational costs can justify the initial investment. Evaluating the technology and efficiency of the unit is crucial in determining its overall value and suitability for specific applications.

Unit Capacity and Scale

The capacity of a thermal desorption unit, which refers to the volume of material it can process within a given timeframe, is a key factor influencing its price. Larger capacity units designed to handle higher volumes of contaminated material generally come with a higher price tag. The scale of operation required will determine whether a high-capacity unit is necessary or if a smaller, more cost-effective model will suffice.

The scale of operation also affects the overall investment, as larger units often require more extensive infrastructure and support systems. Assessing the capacity needs based on the anticipated volume of material to be processed is essential in selecting the appropriate unit and managing investment costs effectively.

Material Quality and Durability

The quality of materials used in the construction of a thermal desorption unit plays a significant role in its pricing. Units constructed with high-grade, corrosion-resistant materials and durable components tend to have a higher initial cost. These materials ensure the longevity and reliability of the equipment, especially when dealing with harsh operating conditions and corrosive substances.

Investing in a unit made from high-quality materials can result in lower maintenance costs and longer operational life, offsetting the higher initial price over time. The durability of the equipment is a critical consideration, as it impacts both the performance and the total cost of ownership.

Customization and Features

Customization options and additional features also affect the thermal desorption unit price. Units that offer customizable configurations, such as varying processing capacities, specialized feed systems, or enhanced safety features, are generally more expensive. These customizations allow the unit to be tailored to specific needs, improving its effectiveness for particular applications.

Features such as advanced control systems, integrated automation, and sophisticated data analytics can further increase the price. While these features add to the initial investment, they contribute to greater operational efficiency and improved process control. Evaluating the necessity and benefits of these additional features is crucial in determining their impact on the overall investment.

Brand and Manufacturer Reputation

The reputation of the brand and manufacturer can influence the price of a thermal desorption unit. Established manufacturers with a history of producing reliable and high-quality equipment often command higher prices due to their proven track record and reputation for excellence. These manufacturers typically offer robust after-sales support, warranties, and service agreements, which can add value to the investment.

Choosing a reputable manufacturer with a strong track record can provide assurances regarding the performance and reliability of the unit. While such units may come with a higher price, the added value in terms of support and performance can be a significant factor in the investment decision.

Compliance and Certification

Compliance with industry standards and certifications impacts the thermal desorption unit price. Units that meet stringent regulatory requirements and hold certifications for safety, environmental impact, and performance generally come at a higher cost. Compliance ensures that the unit adheres to necessary standards, which can be crucial for regulatory approval and operational legitimacy.

Certifications from recognized bodies reflect the quality and reliability of the equipment, influencing its price. Investing in a unit that complies with relevant standards and regulations can help mitigate risks associated with non-compliance and ensure smoother operations.

Operational and Maintenance Costs

Operational and maintenance costs are essential considerations when evaluating the total cost of investing in a thermal desorption unit. These costs include energy consumption, routine maintenance, and potential repairs. Units designed with energy-efficient technologies and low-maintenance components can reduce operational costs and enhance the overall return on investment.

Regular maintenance and servicing are crucial for ensuring the longevity and performance of the unit. The cost of maintenance and the availability of spare parts should be factored into the investment decision to understand the long-term financial implications.

Economic and Market Conditions

Economic and market conditions can impact the thermal desorption unit price. Fluctuations in the cost of raw materials, changes in supply chain dynamics, and variations in currency exchange rates can all affect pricing. Global economic conditions and trade policies may also influence the cost of importing or exporting equipment.

Staying informed about economic trends and market conditions can help in anticipating potential changes in unit pricing and planning investment strategies accordingly. Monitoring these factors ensures that investors are prepared for any fluctuations that may impact the cost of the thermal desorption unit.

Risk Management and Mitigation

Investing in a thermal desorption unit involves inherent risks that must be managed to ensure a successful investment. Key risks include technical failures, operational inefficiencies, and regulatory changes. Implementing risk management strategies, such as selecting a reputable manufacturer, conducting thorough testing, and maintaining compliance with regulations, can help mitigate these risks.

Developing a comprehensive risk management plan and establishing contingency measures can enhance the stability and success of the investment. Ensuring that potential risks are addressed proactively will contribute to a more secure and profitable investment.

Strategic Considerations

Strategic considerations play a crucial role in the investment decision for a thermal desorption unit. Conducting a detailed feasibility study to assess the financial viability, technical requirements, and market potential of the unit is essential. This study provides insights into the expected return on investment and helps in making informed decisions.

Developing a clear business model that outlines the revenue streams, cost structure, and market strategy can enhance the investment’s success. A well-defined business model aligns the investment with market needs and opportunities, improving the overall effectiveness and profitability of the thermal desorption unit.

Conclusion

Investing in a thermal desorption unit requires careful consideration of various factors that influence its price and overall value. Technology and efficiency, unit capacity, material quality, customization, and manufacturer reputation all play significant roles in determining the investment cost. Compliance, operational costs, economic conditions, and risk management strategies further impact the investment decision.

By thoroughly evaluating these considerations and conducting a comprehensive feasibility study, stakeholders can make informed decisions and optimize their investment in a thermal desorption unit. Understanding the various factors that affect the price and performance of the unit will contribute to a successful and profitable investment.