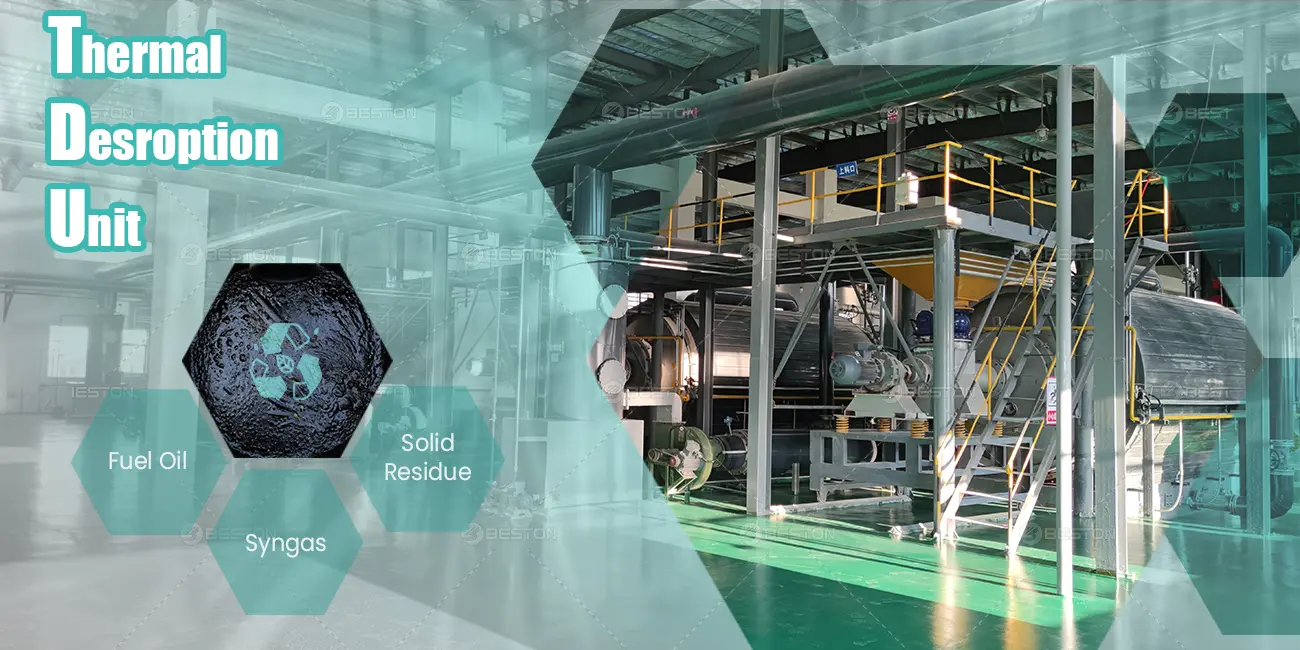

Thermal desorption has become a widely adopted technology for treating hydrocarbon-contaminated sludge. By applying controlled heat to separate volatile compounds from solid matrices, thermal desorption unit (TDU) systems allow recovery of oil components while rendering waste non-hazardous. Their adaptability and high treatment efficacy make them suitable across a range of industrial scenarios, particularly in sectors facing stringent environmental compliance requirements and waste minimization mandates.

Upstream Oilfield Waste Management

Oil drilling and exploration operations generate large volumes of oil-based mud and drill cuttings. These materials typically contain 5–15% residual hydrocarbons and must be treated before disposal or reuse. Thermal desorption unit is often deployed at well sites or centralized waste management hubs to process these residues in situ.

In upstream settings, mobile or skid-mounted units are favored due to their ease of relocation. The treatment cycle generally heats sludge to 300–500°C, effectively recovering oil fractions for reuse in drilling operations. The treated solids can be landfilled as non-hazardous waste or repurposed for construction fill, depending on local regulations.

Refinery Sludge Treatment

Refineries generate complex sludge streams during tank bottom cleaning, API separator operation, and desalter units. These sludges consist of emulsified oil, water, and fine solids. An oil sludge pyrolysis plant provides an efficient method to break the emulsion and recover usable hydrocarbons, thereby reducing waste volumes sent to hazardous landfills.

Refinery-based desorption systems are typically continuous-feed and high-capacity, integrated into existing waste processing infrastructure. The recovered oil often meets quality benchmarks for blending with lower-grade fuels, providing a direct economic offset to treatment costs.

Petrochemical and Tank Farm Operations

Petrochemical plants and fuel storage facilities frequently face accumulation of bottom sludge in tanks and separators. These residues not only reduce storage efficiency but also pose safety hazards. Deploying a thermal desorption unit enables both environmental compliance and hydrocarbon recovery.

In these applications, TDUs are used periodically as part of scheduled tank maintenance. Treatment temperatures are carefully controlled to avoid degradation of valuable light fractions. The separated oil is reintroduced into feedstock streams, while water is treated via conventional wastewater systems. Residual solids, free of volatiles, can be stabilized or used in secondary applications such as road base or aggregate.

Port and Marine Waste Handling

Marine bilge waste and slop oil from ship cleaning activities present logistical and environmental challenges. Coastal and inland port authorities increasingly rely on thermal desorption to manage this waste in an efficient, environmentally responsible manner.

Port-based TDUs are configured to process emulsified marine sludge with high water content. Pre-dehydration and feedstock conditioning steps are integrated to optimize throughput. The modular design of such systems allows for rapid installation and integration with existing marine waste collection frameworks.

Emergency Response and Remediation

In spill response scenarios, TDUs offer a rapid-deployment option for on-site treatment of contaminated soils and sludge. Whether from pipeline ruptures or surface spills, hydrocarbon-impacted material can be thermally treated, avoiding costly off-site transport and disposal.

Mobile TDU systems are designed for rugged, remote environments and can be operated with minimal infrastructure. They play a vital role in reducing ecological damage while recovering residual hydrocarbons from surface-level contamination.

Industrial Sludge from Manufacturing Processes

Beyond the energy sector, several industries—such as paint, lubricant, and metalworking fluids—generate oily sludge requiring specialized handling. Thermal desorption offers a standardized, scalable approach for converting hazardous sludge into benign solid waste, water, and recyclable oil.

These systems can be tailored for variable input composition and are often operated in batch mode. Regulatory incentives and internal sustainability targets are increasingly driving adoption in non-petroleum sectors.

Integration with Circular Economy Models

The deployment of a thermal desorption unit transforms waste from a disposal liability into a source of recoverable energy and reusable material. In jurisdictions with resource recovery legislation or circular economy mandates, TDUs help industries meet recycling targets and reduce landfill dependency. They also support carbon accounting goals by minimizing the need for incineration or fossil-derived replacements.

Whether mobile or stationary, small-scale or industrial-grade, the TDU plays a pivotal role in responsible hydrocarbon waste management across multiple operational landscapes. Its application scenarios will continue to expand in line with tightening environmental frameworks and evolving resource efficiency imperatives.