Sawdust, a byproduct of woodworking, furniture manufacturing, and various lumber industries, holds significant promise in the production of charcoal. Traditionally, wood logs and larger branches have been the primary materials for charcoal production, but the increasing availability of sawdust presents an opportunity to diversify feedstock sources and optimize production methods. With the right equipment and process optimization, sawdust can be converted into high-quality charcoal, contributing to sustainable resource utilization and waste reduction.

Key Characteristics of Sawdust for Charcoal Production

Sawdust's suitability for charcoal production depends largely on its composition, including its moisture content, density, and carbon content. These characteristics play a significant role in determining the efficiency and quality of the charcoal produced.

1. High Carbon Content

Sawdust is primarily composed of cellulose, hemicellulose, and lignin. During pyrolysis, these organic compounds break down under high heat in an oxygen-limited environment. The resulting solid material, biochar or charcoal, consists of carbon-rich structures. The carbon content of sawdust-derived charcoal is typically high, making it a valuable fuel source for a variety of industrial applications.

2. Moisture Content

One of the challenges with sawdust is its relatively high moisture content, especially if it is freshly produced. Wet sawdust must undergo drying before it can be effectively processed into charcoal. Excess moisture in the sawdust can hinder the pyrolysis process, leading to inefficiency in energy consumption and lower-quality charcoal. Drying sawdust can be done through natural or mechanical methods, but this adds an extra step in the overall process.

3. Particle Size and Uniformity

Sawdust is a finely ground material with relatively small particle sizes, which can be advantageous in pyrolysis. The small particle size allows for more uniform heating during the pyrolysis process, enabling efficient thermal decomposition. However, for optimal results, it's important to maintain consistency in the particle size, as unevenly sized sawdust can cause inconsistencies in charcoal quality.

Charcoal Production Process Using Sawdust

The conversion of sawdust to charcoal involves a process known as pyrolysis, which takes place inside a charcoal making machine. This thermochemical process occurs in an environment with limited oxygen, where sawdust is heated to temperatures between 400°C and 700°C. The heat causes the sawdust to break down, releasing volatile gases and liquids, leaving behind solid charcoal.

The general steps for producing charcoal from sawdust are:

-

Drying: To reduce the moisture content of sawdust, it must be dried before being fed into the pyrolysis unit. Drying can be accomplished using heat from the pyrolysis plant or through external drying equipment, such as rotary dryers or conveyor dryers.

-

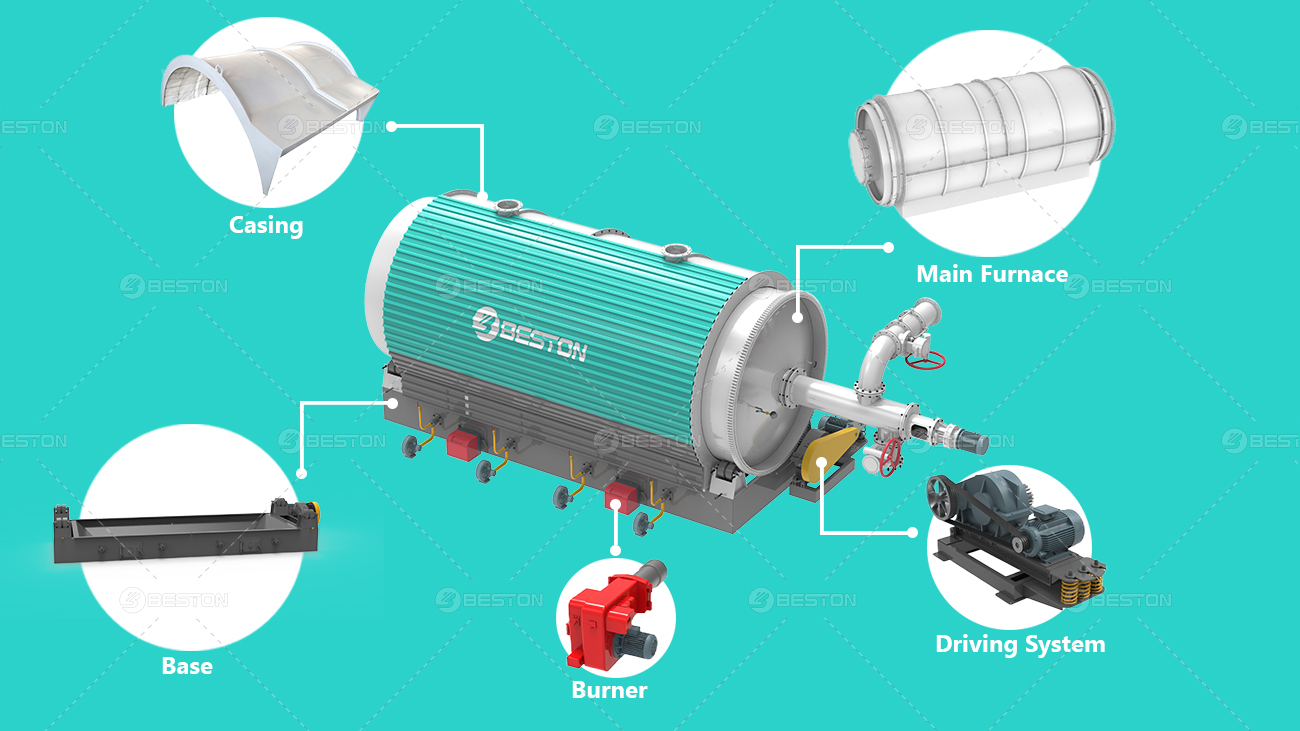

Pyrolysis: The dried sawdust is then fed into the charcoal machine, where it undergoes pyrolysis. The machine provides the necessary heat and conditions for the chemical transformation of sawdust into charcoal.

-

Cooling: After the pyrolysis process is completed, the resulting charcoal must be cooled to ensure it is stable and safe for handling. This step can also be performed inside the pyrolysis unit using controlled cooling techniques to prevent the charcoal from catching fire.

-

Packaging: Finally, the charcoal is packaged for storage or distribution. The high carbon content and energy density of the charcoal make it an ideal fuel for industrial and residential use, especially in areas where traditional charcoal resources are scarce.

Advantages of Using Sawdust for Charcoal Production

Sawdust, when processed into charcoal, offers several environmental, economic, and logistical advantages:

1. Waste Utilization

Sawdust is often seen as a waste product from woodworking and furniture industries. Rather than allowing this material to be discarded or burned, converting it into charcoal offers a sustainable solution for waste management. By utilizing sawdust, the demand for raw wood resources can be reduced, alleviating pressures on forests and promoting the use of byproducts.

2. Higher Charcoal Yield

Sawdust typically has a higher yield in charcoal production compared to larger wood logs, due to its smaller particle size and higher surface area. This results in faster and more efficient pyrolysis, which leads to increased charcoal production in less time.

3. Energy Efficiency

The small size of sawdust particles means that they heat up quickly and evenly during the pyrolysis process. This efficiency reduces energy consumption and makes the process more cost-effective. The energy released during the pyrolysis process can also be captured and used to fuel the operation of the charcoal machine, further reducing operational costs.

4. Reduced Environmental Impact

The use of sawdust for charcoal production helps reduce the environmental impact of forest resource extraction. Instead of relying solely on virgin wood, which requires the cutting down of trees, sawdust provides a more sustainable feedstock option. Additionally, since sawdust is often generated as a byproduct, it minimizes waste disposal problems and lowers the carbon footprint associated with traditional wood harvesting.

Factors to Consider in Choosing a Charcoal Machine for Sawdust

Not all charcoal machines are designed to handle sawdust effectively, and choosing the right equipment is crucial to maximizing production efficiency and ensuring high-quality output. Here are some factors to consider when selecting a charcoal machine for sawdust:

-

Size and Capacity: Ensure that the machine can accommodate the volume of sawdust produced and meet the production requirements. Large-scale operations will require higher-capacity machines to ensure efficient processing.

-

Fuel Efficiency: Look for a machine that can utilize the heat generated during the pyrolysis process for energy recovery. This can significantly reduce the cost of operations by minimizing external fuel consumption.

-

Automation and Control Systems: Advanced charcoal machines are equipped with automation features, allowing for precise control over temperature, feed rate, and pyrolysis duration. These systems help optimize the production process and maintain consistent product quality.

-

Maintenance Requirements: Regular maintenance is essential for ensuring the longevity and efficiency of a charcoal machine. Choose equipment that is durable, easy to maintain, and supported by a reliable service provider.