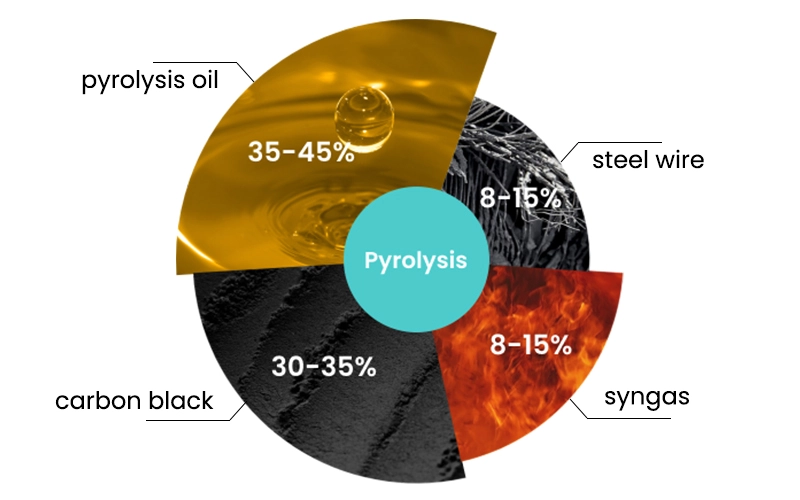

Tire pyrolysis oil, a byproduct of the tire pyrolysis plant, has gained significant attention due to its versatility and potential applications in various industries. As the demand for sustainable energy solutions grows, understanding the sales channels for tire pyrolysis oil becomes imperative for maximizing profitability and market reach. This article explores the various avenues through which tire pyrolysis oil can be marketed and sold.

Direct Sales to Refineries

One of the primary sales channels for tire pyrolysis oil is direct sales to oil refineries. Many refineries are increasingly seeking alternative feedstocks to supplement their traditional crude oil supplies. Tire pyrolysis oil can serve as a suitable substitute due to its similar chemical composition, allowing refineries to process it into various petroleum products.

Establishing direct relationships with refineries can yield lucrative contracts, as these facilities often operate on a large scale and require consistent supply. Producers of tire pyrolysis oil must ensure their product meets the necessary quality standards to attract refinery partnerships. This includes adhering to specifications regarding viscosity, sulfur content, and calorific value, which can vary based on the refinery's processing capabilities.

Industrial Fuel Market

Another significant avenue for selling tire pyrolysis oil is the industrial fuel market. The oil can be utilized as an alternative fuel in various industrial applications, including cement production, power generation, and heating processes. Its high calorific value makes it an attractive option for industries seeking to reduce their reliance on fossil fuels.

Marketing tire pyrolysis oil to industries that prioritize sustainability can lead to strong demand. Establishing partnerships with companies focused on reducing their carbon footprint will enhance the marketability of tire pyrolysis oil as a green alternative. Furthermore, providing case studies or performance data demonstrating the efficiency of tire pyrolysis oil in industrial applications can bolster credibility and encourage adoption.

Distribution through Wholesale Channels

Wholesale distribution represents another promising sales channel for tire pyrolysis oil. Wholesalers can help bridge the gap between producers and end-users by facilitating bulk transactions. This channel is particularly beneficial for producers who may not have the resources or market reach to engage directly with large-scale buyers.

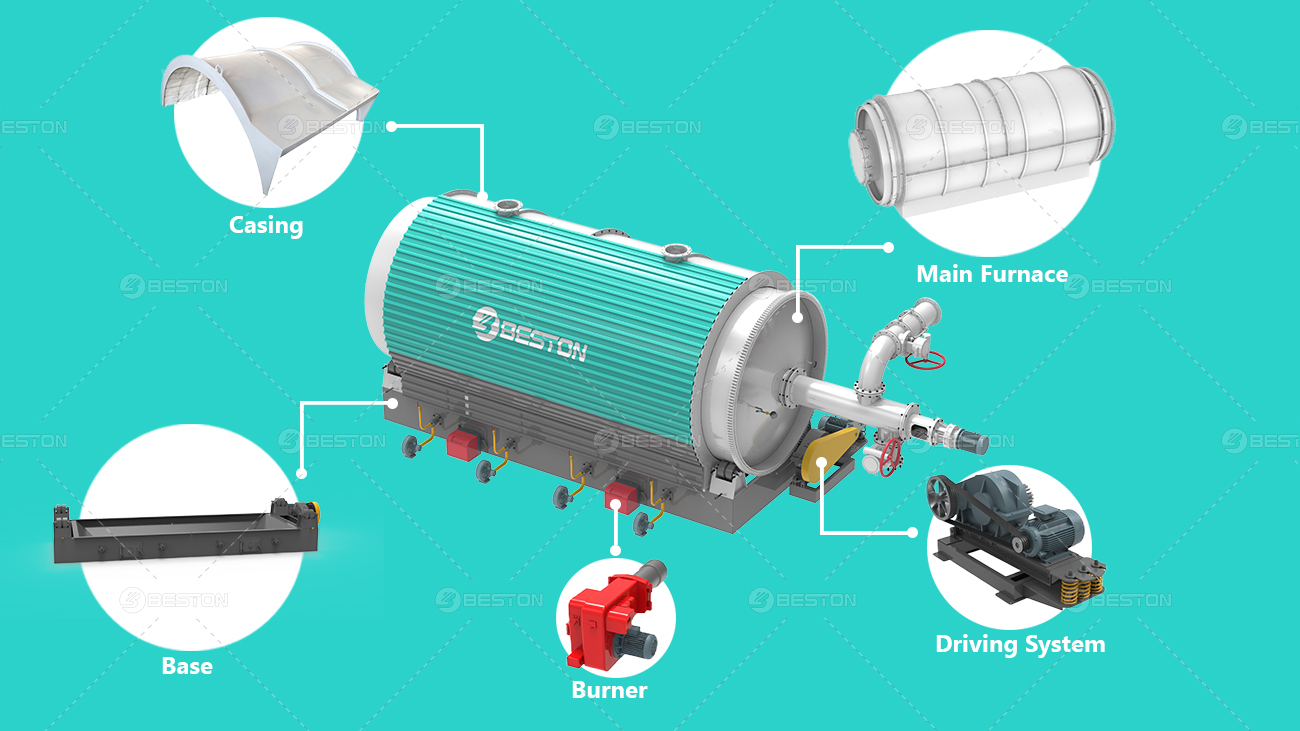

Collaborating with established wholesalers can provide access to broader markets and networks. It is essential to negotiate favorable terms and conditions that reflect the value of the tire pyrolysis oil from tire pyrolysis reactor while ensuring competitive pricing for wholesalers. Building strong relationships within this channel can lead to long-term partnerships and sustained sales.

Export Markets

The global demand for alternative energy sources opens up lucrative opportunities in export markets. Countries with limited access to traditional energy resources or those striving to enhance their renewable energy portfolios represent significant potential buyers for tire pyrolysis oil.

Navigating international regulations and compliance requirements is critical when pursuing export opportunities. Understanding the target country's standards for fuel quality and safety is essential for successful entry into foreign markets. Participating in trade shows and industry exhibitions can facilitate connections with international buyers and distributors.

Online Marketplaces

The rise of digital platforms has revolutionized the way products are marketed and sold. Online marketplaces present an innovative channel for promoting tire pyrolysis oil. Producers can create dedicated websites or utilize existing platforms to reach a wider audience.

Effective digital marketing strategies, including search engine optimization (SEO) and social media engagement, can enhance visibility and attract potential buyers. Offering detailed product specifications, certifications, and testimonials on the website can help build trust and credibility with prospective customers.

Partnerships with Energy Providers

Collaborating with energy providers can create additional sales channels for tire pyrolysis oil. As energy companies diversify their portfolios to include renewable and alternative energy sources, tire pyrolysis oil can be positioned as a viable option for blending with traditional fuels.

Such partnerships can facilitate large-scale contracts, providing a steady revenue stream. It is crucial to communicate the environmental benefits of using tire pyrolysis oil, including its lower carbon emissions compared to conventional fuels.

Conclusion

The sales channels for tire pyrolysis oil are diverse, each offering unique opportunities for producers. From direct sales to refineries and industrial applications to wholesale distribution and export markets, the avenues for marketing this valuable product are extensive. By understanding and strategically navigating these channels, producers can enhance their market presence, drive sales, and contribute to a more sustainable energy future.